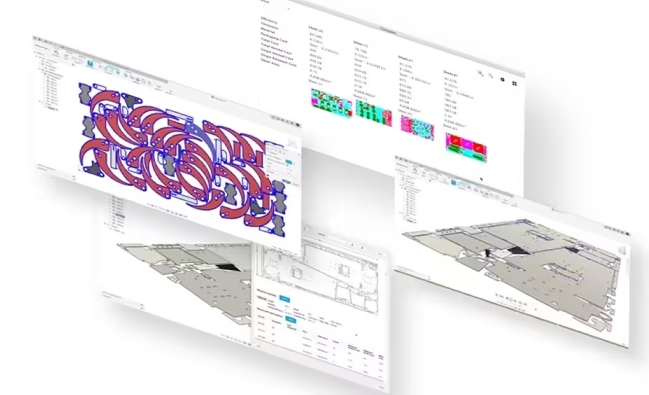

Nesting & Fabrication Extension

The extension is a powerful tool for optimizing the sheet metal (or other 2D shapes laid out in a planar surface).

It automatically arranges parts on the sheet, minimizing waste and maximizing efficiency.

Nesting is a key step in sheet metal production and can have a significant impact on your bottom line.

The extension uses artificial intelligence algorithms to automatically place parts on the sheet. These algorithms take various factors into account,

including part shape and size, available space on the sheet, and accuracy requirements.

Advantages of the extension:

Waste reduction: Reducing waste can lead to cost savings and improved sustainability.

Increased efficiency: Increasing the efficiency of sheet metal production can lead to reduced production time and costs.

Improved accuracy: Improving the precision of sheet metal production can lead to a reduction in the number of scrap parts and an increase in customer satisfaction.

The extension is integrated into Fusion, making it very intuitive to use. After creating a 3D model of the parts, it is possible to import them into Nesting.

Nesting then automatically creates a cutting plan design. This design can be modified as required.