Simulation Extension

The extension allows your team to analyze performance and manufacturability. Simulation study types help you understand how your 3D designs behave in real-world conditions before you start producing anything.

Strength and plastic injection simulation will reveal potential bottlenecks, and these can be modified early in the process to avoid expensive modifications to already finished parts.

Extension benefits

Access to a diverse number of simulations: The extension provides access to a wide range of advanced finite element analysis (FEA) simulation functions for the ability to simulate design performance under a variety of real-world conditions.

Simplification of CAD simulation models: The extension simplifies the process of creating and running simulation studies on CAD models, making it possible to compare design changes and make revisions without having to export models,

saving time and eliminating the risk of errors.

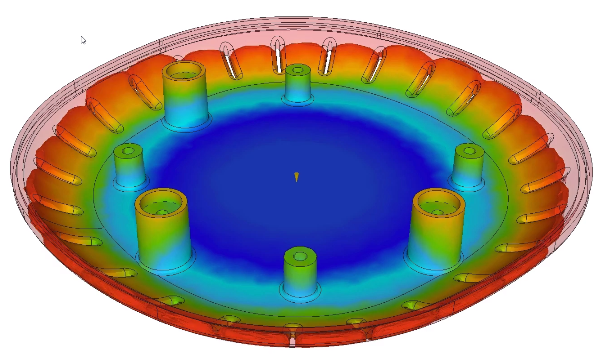

Ensuring mouldability of plastic parts: The extension can be used to detect and visualise moulding problems and predict the quality of plastic parts being injection moulded. For manufacturability purposes,

the It is possible to incorporate the suggested changes recommended by the software into 3D models.

Simulation functions

- Plastic injection moulding simulation: Simulation of part design to influence manufacturability and part quality for plastic injection mold parts.

- Unconventional static tension: Simulation of large deformation, motion, contact and load change behaviour on non-linear materials.

- Event simulation: Prediction of the force over time affecting the performance of a 3D product.

- Thermal balance: Monitor heat transfer to understand if and when a part may fail based on the maximum critical temperature.

- Frequency frequencies: Monitor the effects of natural and free vibration on a part or assembly to fine-tune the design.

- Bending curve: Improving the design using insights such as critical bending multiplicity to prevent structural failure.

- Temperature stress: Simulation of temperature-induced stresses and different thermal expansion properties of materials in the model.

- Shape optimization: Achieve lightweight design goals by identifying and removing material from designs.

Fusion Simulation Extension is a valuable tool for analyzing the performance and manufacturability of 3D designs. It provides a wide range of simulation options, simplifies the simulation process and helps ensure manufacturability of designs.